From Prototypes To Large Volume Automated Production

SECO MACHINE – CONCEPTS TO REALITY

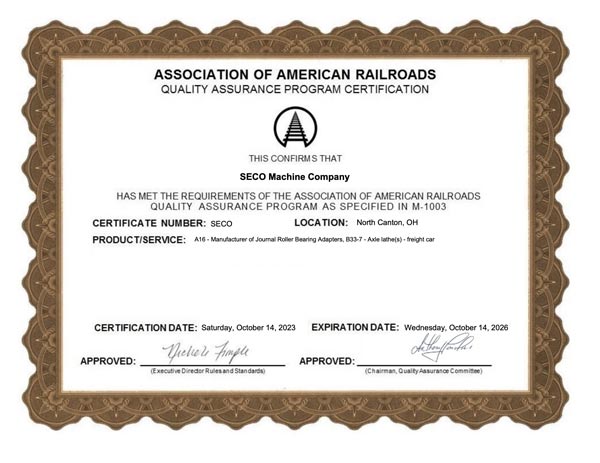

Seco Machine – Industry Leader

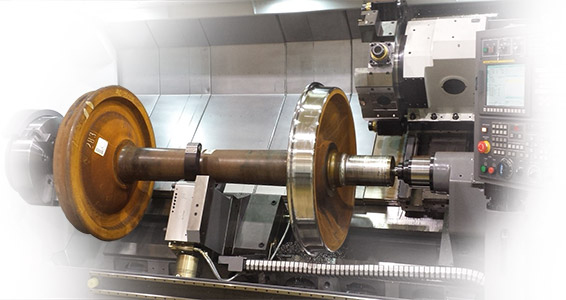

Established in 1985, Seco Machine continues to lead the industry in comprehensive contract manufacturing. Machining is the heart of our organization, primarily turning, milling and some grinding capabilities.

Exceeding expectations usually go beyond just machining, which is why we take a great deal of pride in our high level of customer service and the broad array of ancillary services we offer. We strive to work closely with each customer to exceed their expectations in all areas.

Our Ancillary Services include but are not limited to warehousing of raw and finished materials for JIT delivery, production sawing, light assembly, heat treatment, various coatings and specialty packaging for drop shipments. We also specialize in manufacturing our own foundry tooling and conversion of expensive materials like steel forgings to more cost effective grey, ductile and austempered ductile iron castings.

We have put considerable effort in becoming an industry leader in machining ADI (austempered ductile iron). We regularly machine ADI to a hardness of about 500 brinell. This is possible largely due to the development of our own specialty tooling and coolant formulas.

OUR CAPABILITIES

- WAREHOUSING & SHIPPING

Seco Machine has JIT shipping of many individual parts and assembled components as well as a rapidly growing shipping and receiving department.

- DRILLING AND BORING

From prototypes to large volume automated production of plastic to Inconel.

- CONTRACT MACHINING

Some of our precision machined products include Backing Rings, Axle End Caps, Plugs, Bearing Cones, Side Bearings, Yoke Bushings, Center Pins and more.

- AUTOMATION

performing multiple operations at once, with no human interaction, which enables employees to focus on more complicated tasks and greater precision